Grasping In-Mold Decorations: Approaches, Patterns, and Best Practices for Optimal Results

In the realm of production, the art of in-mold decorations stands as a crucial facet of item layout and manufacturing. In-Mold Decorations. By delving into the techniques, fads, and ideal methods that underpin effective in-mold design procedures, organizations can open a realm of opportunities that not just raise the visual appeal of their products however also streamline manufacturing performance and bolster customer engagement.

Material Choice

Material option is a crucial facet of grasping in-mold decorations, as it directly affects the high quality and toughness of the end product. When picking materials for in-mold decorations, it is crucial to consider variables such as compatibility with the molding process, the preferred aesthetic result, and the ecological problems the product will deal with. Thermoplastic materials like polypropylene, abs, and polycarbonate are frequently used for in-mold designs due to their convenience and capacity to accomplish elaborate layouts. These materials use excellent moldability, enabling manufacturers to create intricate forms and patterns with precision.

Moreover, the picked material ought to possess good adhesion residential properties to make certain that the design adheres securely to the substratum during the molding procedure. Adhesion between the decor and the product is crucial for stopping delamination and ensuring long-lasting visual charm. In addition, materials with high warm resistance are preferred for in-mold decors, especially for items that will be revealed to elevated temperature levels during their lifecycle. By carefully picking the appropriate product for in-mold decors, makers can enhance the total quality and resilience of their products, satisfying the expectations of both end-users and clients.

Design Innovation

An important consider progressing the field of in-mold decorations is the constant exploration and implementation of design development techniques. Layout advancement plays a critical function in enhancing the aesthetic charm, performance, and general high quality of products manufactured utilizing in-mold decor processes. By including ingenious design elements, makers can differentiate their items out there, bring in customers, and remain in advance of rivals.

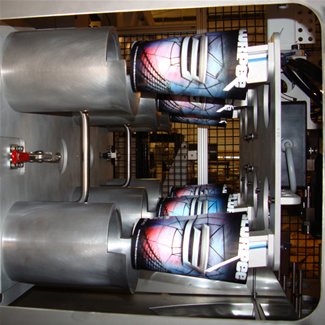

One of the vital facets of layout advancement in in-mold decors is the integration of elaborate patterns, appearances, and graphics that were formerly testing to achieve with conventional decoration approaches. Advanced technologies such as 3D printing and digital design devices allow designers to develop complex and comprehensive layouts that can be flawlessly moved onto molded components. Additionally, using lively shades, metal surfaces, and unique results like gloss or matte structures can better elevate the aesthetic appeal of in-mold decorated items.

Additionally, design advancement prolongs past appearances to encompass useful enhancements such as ergonomic shapes, integrated attributes, and adjustable elements that provide to details customer needs. By accepting design advancement, manufacturers can open new opportunities for creativity, personalization, and product differentiation in the affordable landscape of in-mold decorations.

Production Efficiency

Reliable manufacturing procedures are necessary for converting the innovative layouts developed in the field of in-mold decors right into top quality completed items that satisfy market demands and customer assumptions. In the world of in-mold decorations, manufacturing performance encompasses numerous essential facets that add to the total success of the manufacturing procedure.

Additionally, executing automation and robotics in the assembly line can considerably enhance performance by improving repeated tasks and minimizing the margin of error. Automation not only accelerates the production procedure but also improves precision and repeatability, resulting in a much more high-quality and uniform final result. Moreover, taking on lean manufacturing concepts, such as just-in-time stock monitoring and waste decrease strategies, can further boost production effectiveness by lessening downtime and maximizing resource usage. Generally, a holistic technique to manufacturing effectiveness is vital in making best use of the capacity of in-mold design techniques and accomplishing ideal lead to the open market landscape.

High Quality Control Procedures

What are the vital techniques for making certain rigid top quality control steps in the world of in-mold designs? Quality assurance actions are paramount in in-mold design processes to guarantee the production of high-grade and perfect finished products. One vital approach is the implementation of rigorous inspection protocols at every phase of the production process. This involves carrying out comprehensive aesthetic assessments, dimensional checks, and shade uniformity evaluations to identify any flaws or disparities beforehand.

Making use of innovative innovations such as computerized evaluation systems can also improve the quality assurance process by supplying precise and trusted data for evaluation. These systems can spot imperfections that might be missed out on by manual assessments, thereby boosting general item top quality and consistency.

Regular training and advancement programs for workers associated with the in-mold decoration process can also add to keeping top notch requirements. By enlightening personnel on finest practices, quality assumptions, and the significance of focus to information, business can promote a culture of quality awareness throughout the company.

Customer Allure

To enhance the marketability of in-mold decoration items, understanding and catering to customer choices play an essential function in determining their charm and success. Customer allure in in-mold decorations is affected by numerous elements, including layout aesthetic appeals, shade options, toughness, and general functionality. Customers are significantly looking for personalized and special products that show their originality and style. Supplying customization choices such as personalized designs, shade variations, and textural elements can significantly boost the appeal of in-mold Going Here design items.

Conclusion

In-mold decorations use a reliable and functional method to boost item looks. Understanding in-mold designs needs an all natural approach that thinks about all facets of the production procedure to ensure success.

In the world of production, the art of in-mold decors stands as a crucial facet of item style and production. Style advancement plays a vital role in enhancing the visual allure, functionality, and total high quality of items made using in-mold design procedures.One of the vital facets of design development in in-mold decors is the assimilation of detailed patterns, appearances, and graphics that were formerly testing to accomplish with traditional decoration methods.Efficient production processes are crucial for translating the innovative designs developed in the linked here area of in-mold decorations into premium completed items that fulfill market needs and customer assumptions. Supplying modification options such as personalized designs, shade variants, and textural components can considerably boost the appeal of in-mold design items.